- Home Page

- Company Profile

-

Our Products

- Coating Products

- Amber Color CBN A80 Powder Vitrified Bond For Grinding Wheel

- Amber Color Powder Vitrified Bond For Grinding Wheel

- Amber Color CBN A80 Powder

- Amber Color CBN Cubic Boron Nitride Powder Vitrified Bond

- Different Grain Size Diamond Powder Titanium Coating

- Mesh And Micron Coated Industrial Diamond Powder For Grinding

- Micron Industrial Diamond Powder Nickel Coating For Grinding

- CBN A80 Super Abrasive Materials

- Titanium Coating Diamond CBN Powder And Nickel Coated Synthetic Diamond

- Coated Industrial Diamond Powder

- Industrial Using Synthetic Monocrystalline Diamond

- Crystal Diamond Mesh Micro Powder

- Single Crystal Synthetic Industrial Diamond

- Synthetic Industrial Diamonds

- Synthetic Diamond Powder For Polishing

- Synthetic Single Crystal Diamond Powder For Grinding

- Single Crystal Synthetic Industrial Diamond Powder

- Cubic Boron Nitride Micro Powder

- Cubic Boron Nitride CBN Cubic Boron Nitride Micro Powder

- Cubic Boron Nitride CBN Single Crystal Diamond

- Synthetic Single Crystal Diamond Powder Diamond Micron For Stone Cutting Blade

- Synthetic Single Crystal Diamond Powder Diamond Mesh

- Synthetic Single Crystal Diamond For Diamond Grinding Wheels

- Diamond Mesh Micro Powder

- Multinano Crystal Diamond Micro Powder

- High Quality Diamond Dust

- CBN Dust And Diamond Powder

- Polishing Metals

- Smooth And Efficient Grinding Materials

- CBN And Diamond Powder With High Quality

- Synthetic Diamond And CBN Powder

- Supperabrasives Synthetic Diamond Micron Powder For Grinding Wheel

- Titanium Coating Synthetic Diamond Or CBN Powder

- Superabrasive Diamond Powder Polycrystalline -Multinano-Crystal Diamond Micro-Mesh Powder

- CBN Insert And Cutting Tools

- Solid CBN Insert Sngn1507 For Hardened High Chrome Steels

- High Abrasion Resistance PCBN Diamond Indexable Cutting Inserts

- CBN Insert Metal Lathe Cutting Tools

- PCBN Cutter For Finishing Roller

- Solid PCBN Inserts Cutting Tools Used In Brake Disc And Brake Hub

- Solid CBN PCBN Inserts For Machining Cast Iron Metal Lathe Tools

- High Cost Performance CNC-CBN Turning Inserts

- High Precision Cutting Tool Lathe Used Carbide Insert

- Cubic Boron Nitride Mesh Micro Powder

- Resin Bond Mesh

- Synthetic Multinano-Crystal Diamond Powder Used For Heavy Grinding Duty

- High Synthetic Diamond Used For Grinding Wheel

- Premium Synthetic Diamond

- Synthetic Polycrystalline Diamond

- Titanium Coated Ceramic Bond Diamond Powder

- Supper Fine Abrasives Synthetic Diamond Micron Powder For Grinding Wheel

- Monocrystalline Polycrystalline Micro Synthetic Diamond Polishing Powder

- Synthetic Diamond Powder Used For Heavy Grinding Duty

- Industrial Diamond Powder With 60 Percent Nickel Coating

- High Quality Synthetic Industrial Diamond For Grinding Or Polishing

- Synthetic Diamond Powder CBN Powder For Processing Diamond Tools

- Vitrified Bond Mesh

- CBN Abrasive Micron Powder For Grinding Wheel

- CBN Powder For Polishing Making CBN Wheel

- Diamond Powder For Making Grinding Wheels

- Super Abrasive to Be Made Diamond Tools

- Nickel Coating CBN Powder Polishing Kinds Of Metal

- High Quality Synthetic Diamond Powder

- Superhard Material Black Diamond More Sharper

- Sharpen Diamond Mesh

- Diamond Powder For Resin Bone Wheels

- Diamond And CBN Powder

- Nickel Coated By 30 Percent And 56 Percent With Diamond Powder

- Metal Bond Micron

- Metal Bond Mesh

- CBN Cubic Boron Nitride for Grinding Wheel Processing Auto Camshaft And Crankshaft

- Angle Grinder Super Abrasive Material Synthetic Diamond

- CBN A80 Powder Used

- Cubic Boron Nitride B5 Powder For Vitrified-Metal Bond Abrasive

- Cubic Boron Nitride A80 Powder Used For Grinding

- Grinding Machine Parts Needs Diamond And CBN Micro Mesh

- CBN And Diamond

- Nickel Plated CBN And Diamond

- CBN-A99 Cubic Boron Nitride

- Diamond Micron Powder

- CBN Powder

- Lab Grown Diamond

- Coating Products

- Contact Us

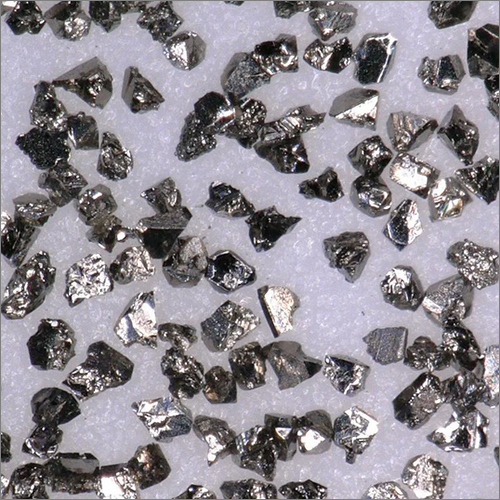

Titanium Coating Synthetic Diamond Or CBN Powder

Product Details:

- Shape Crystal

- Material Synthetic Diamond

- Usage Cutting, Grinding, Lapping, Polishing

- Size Different Available

- Product Type Synthetic Diamond

- Color Black

- Application Industrial

- Click to View more

X

Titanium Coating Synthetic Diamond Or CBN Powder Price And Quantity

- 100 Carat

Titanium Coating Synthetic Diamond Or CBN Powder Product Specifications

- Crystal

- Synthetic Diamond

- Different Available

- Black

- Synthetic Diamond

- Cutting, Grinding, Lapping, Polishing

- Industrial

Titanium Coating Synthetic Diamond Or CBN Powder Trade Information

- Cash Advance (CA)

- 15000000 Carat Per Month

- 5 Days

- All India

Product Description

Under the guidance of our well-trained professionals, the Bescosupera Brasives Company is supplying and manufacturing an assorted range of the Titanium Coating Synthetic Diamond Or CBN Powder. The offered range is made by using the superior quality materials and sophisticated techniques, under the directions of our well-experienced professionals. We ensure to provide the excellent quality Ni coating, Ti coating and Cu coating range of the Titanium Coating Synthetic Diamond Or CBN Powder at budget-friendly prices.

Enhanced Performance for Industrial Applications

Our titanium-coated synthetic diamond and CBN powders deliver superior durability and performance in heavy-duty industrial environments. Designed for cutting, grinding, lapping, and polishing, these powders provide optimal efficiency and extended tool life due to the improved bond afforded by the titanium layer. The diversity in available sizes and the robust crystal shape accommodate a wide range of application needs.

Quality You Can Trust

As a leading manufacturer, exporter, distributor, supplier, and trader in China, we adhere to stringent quality standards to ensure the reliability and consistency of every batch. Each product undergoes comprehensive testing to meet global industry requirements, making it a dependable choice for professional and industrial users worldwide.

FAQs of Titanium Coating Synthetic Diamond Or CBN Powder:

Q: How does titanium coating improve synthetic diamond or CBN powder performance?

A: Titanium coating strengthens the synthetic diamond or CBN powder, increasing thermal stability and enhancing its bonding properties within various tool matrices. This results in better durability, resistance to wear, and the ability to perform efficiently under rigorous industrial conditions.Q: What industrial processes are most suitable for using this coated powder?

A: The titanium-coated synthetic diamond or CBN powder is ideal for cutting, grinding, lapping, and polishing. Its durability makes it suitable for manufacturing tools, precision engineering, and material processing in industries such as automotive, aerospace, and electronics.Q: When should I choose titanium-coated powder over uncoated varieties?

A: Choose titanium-coated powder when your application involves high temperatures, aggressive mechanical stress, or requires prolonged abrasive life. The coating prevents premature wear and improves adhesion in the tool, making it preferable for demanding industrial tasks.Q: Where can I source titanium coating synthetic diamond or CBN powder from China?

A: You can source this high-quality powder directly from reputable manufacturers, exporters, suppliers, and traders in China. We offer a wide selection with different sizes and specifications to meet diverse industrial demands and ensure prompt global delivery.Q: What is the manufacturing process for titanium-coated synthetic diamond or CBN powder?

A: The process begins with high-purity synthetic diamond or CBN crystals, which are carefully cleaned and prepared. A titanium layer is applied using advanced coating techniques, ensuring uniform coverage that maximizes performance in cutting, grinding, and other applications.Q: How is this product typically used in abrasive applications?

A: The powder is embedded into tool matrices or applied to surfaces requiring precision abrasion. Its commonly used in the production of cutting tools, grinding wheels, polishing pads, and other abrasive instruments for industrial processes.Q: What are the main benefits of using titanium-coated synthetic diamond or CBN powder?

A: Key benefits include enhanced durability, greater resistance to thermal and chemical stress, improved tool longevity, and superior performance in challenging industrial environments. The titanium layer ensures better adhesion in bonding systems, making tools more effective and reliable.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email